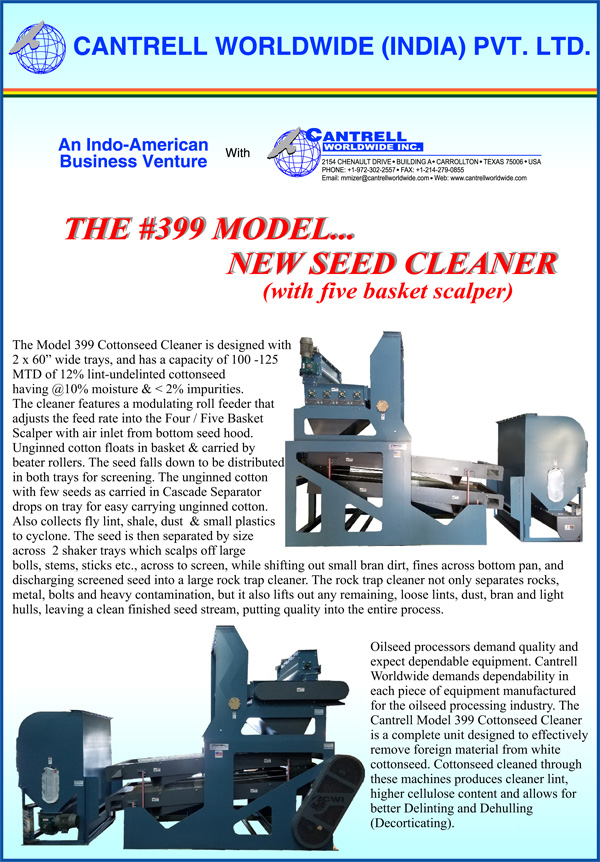

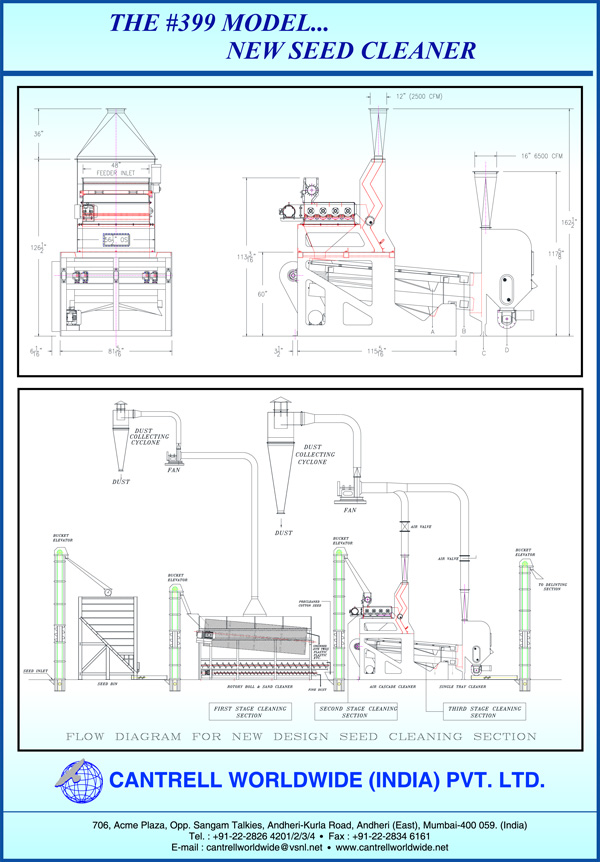

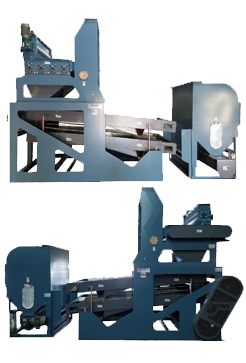

| The Model 399 Cottonseed Cleaner is designed with 2 x 60" wide trays, and has a capacity of 100 -125 MTD of 12% lint-undelinted cottonseed having @10% moisture & < 2% impurities.

The cleaner features a modulating roll feeder that adjusts the feed rate into the Four / Five Basket Scalper with air inlet from bottom seed hood. Unginned cotton floats in basket & carried by beater rollers. The seed falls down to be distributedin both trays for screening. The unginned cotton with few seeds as carried in Cascade Separator drops on tray for easy carrying unginned cotton. Also collects fly lint, shale, dust & small plastics to cyclone. The seed is then separated by size across 2 shaker trays which scalps off large bolls, stems, sticks etc., across to screen, while shifting out small bran dirt, fines across bottom pan, and discharging screened seed into a large rock trap cleaner. |

|

|

|

The rock trap cleaner not only separates rocks, metal, bolts and heavy contamination, but it also lifts out any remaining, loose lints, dust, bran and light hulls, leaving a clean finished seed stream, putting quality into the entire process. Oilseed processors demand quality and expect dependable equipment. Cantrell Worldwide demands dependability in each piece of equipment manufactured for the oilseed processing industry.

The Cantrell Model 399 Cottonseed Cleaner is a complete unit designed to effectively remove foreign material from white cottonseed. Cottonseed cleaned through these machines produces cleaner lint, higher cellulose content and allows for better Delinting and Dehulling (Decorticating).

|

||

Copyright © 2014 – 2015 Cantrell Worldwide (India) Pvt. Ltd. All Rights Reserved. |

Designed by WSS |

|

Home

Home